Metalstampo Srl: Innovation in Aluminum and Zamak Die Casting for Diverse Sectors

- metalstampo srl

- Sep 5, 2024

- 2 min read

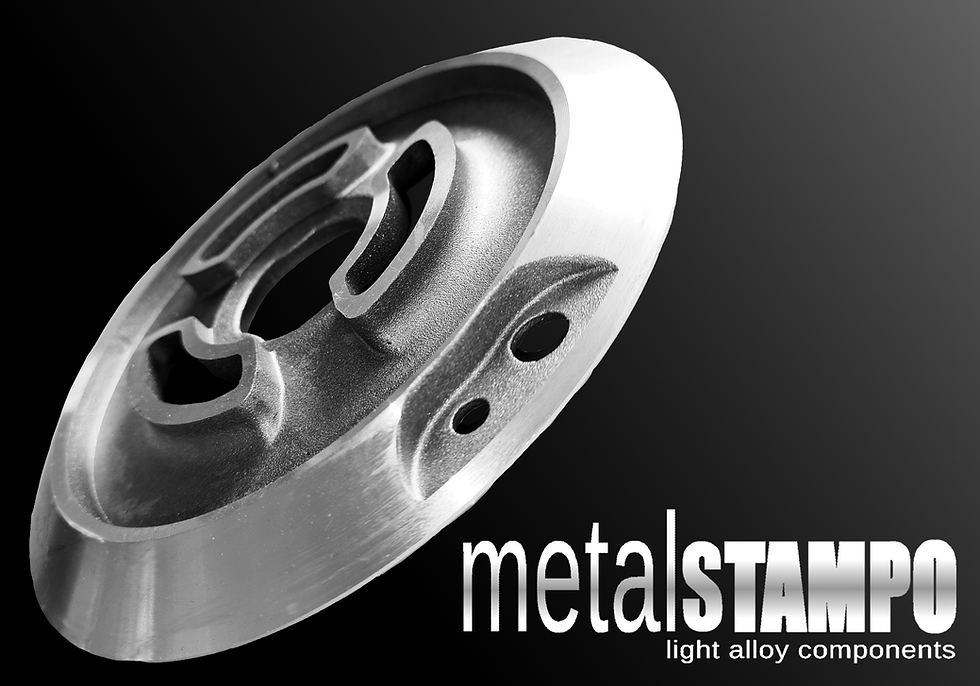

Metalstampo Srl is a leading industrial company in Italy, specializing in aluminum and zamak die casting. Operating across a wide range of sectors, from food to automotive, electromechanics to pneumatics, and emerging fields like green energy and medical technology, the company stands out for its ability to offer innovative and tailored solutions to its clients. With an integrated approach and a focus on design and co-design, Metalstampo positions itself as a strategic partner, supporting clients at every stage of the production process.

Design and Co-Design: A Winning Approach

One of the aspects that make Metalstampo a reliable and innovative partner is its attention to the design phase. In addition to die casting, the company supports clients from the very beginning of the process, closely collaborating in the construction of the necessary equipment. This approach allows for the optimization of every production phase, ensuring high-quality products and increased efficiency.

Since 2020, Metalstampo has introduced a 3D resin printer for rapid prototyping, a tool that has revolutionized the way the design phase is approached. Thanks to this technology, it is possible to create physical models of parts in very short times, allowing clients to quickly visualize and test prototypes before proceeding to mass production.

Technological Collaborations and Material Selection

Another distinguishing element of Metalstampo is its collaboration with leading companies in the production of raw materials. This synergy is essential for selecting the most suitable materials, which vary depending on the target sector and client requirements. In this way, Metalstampo can guarantee custom solutions, using high-quality aluminum and zamak alloys that meet the highest standards of strength, durability, and sustainability.

Aluminum and Zamak Die Casting: Quality and Innovation

The company’s core business remains the die casting of aluminum and zamak, two materials with excellent technical characteristics. Aluminum, known for its lightness and strength, is ideal for applications in the automotive and green sectors, where a combination of high performance and environmental respect is required. Zamak, on the other hand, is valued for its versatility and precision and is widely used in sectors such as furniture, home appliances, and pneumatics.

Metalstampo is distinguished by its use of cutting-edge technologies and highly automated production processes, which guarantee high quality standards and reduced production times. Every phase of the process, from casting to cooling, is carefully monitored to ensure that the produced parts meet the technical specifications and client needs.

Innovation and the Future

Metalstampo’s focus on innovation, sustainability, and quality positions it as a forward-thinking company, ready to face the challenges of an ever-evolving market. With a constant focus on research and development and through strategic collaborations with technological partners, Metalstampo can anticipate trends and offer cutting-edge solutions to its clients.

In a world where customization and production efficiency are increasingly in demand, Metalstampo stands out as a solid and reliable partner, able to respond to the most complex needs with flexibility, expertise, and innovation.

For more information, visit the official website: Metalstampo Srl.

Comments