Metalstampo Srl: High-Precision Aluminum and Zamak Die Casting Plants

- metalstampo srl

- Sep 12, 2024

- 4 min read

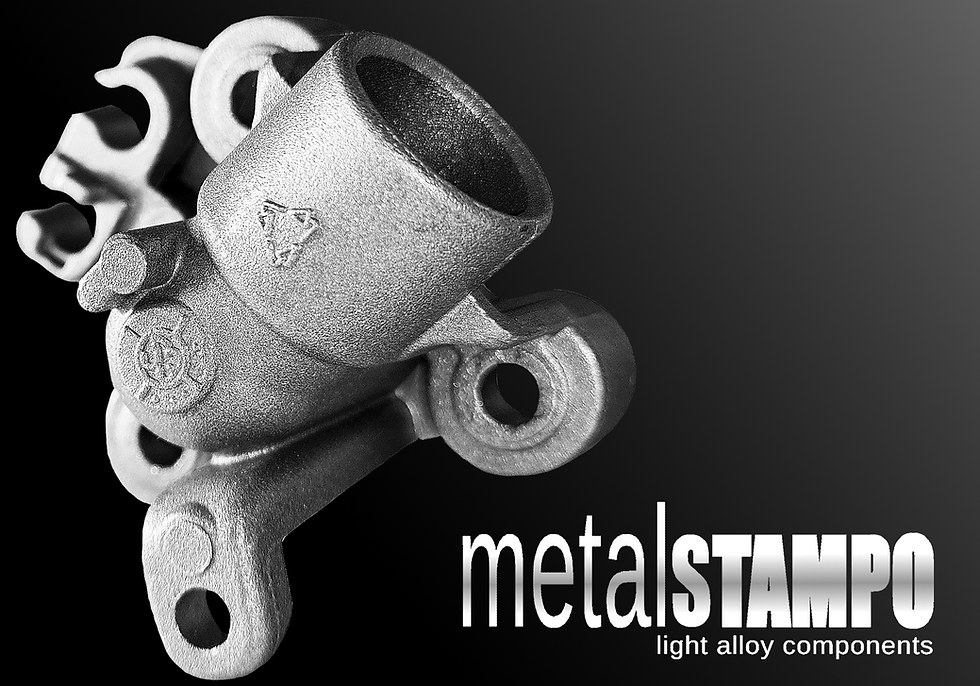

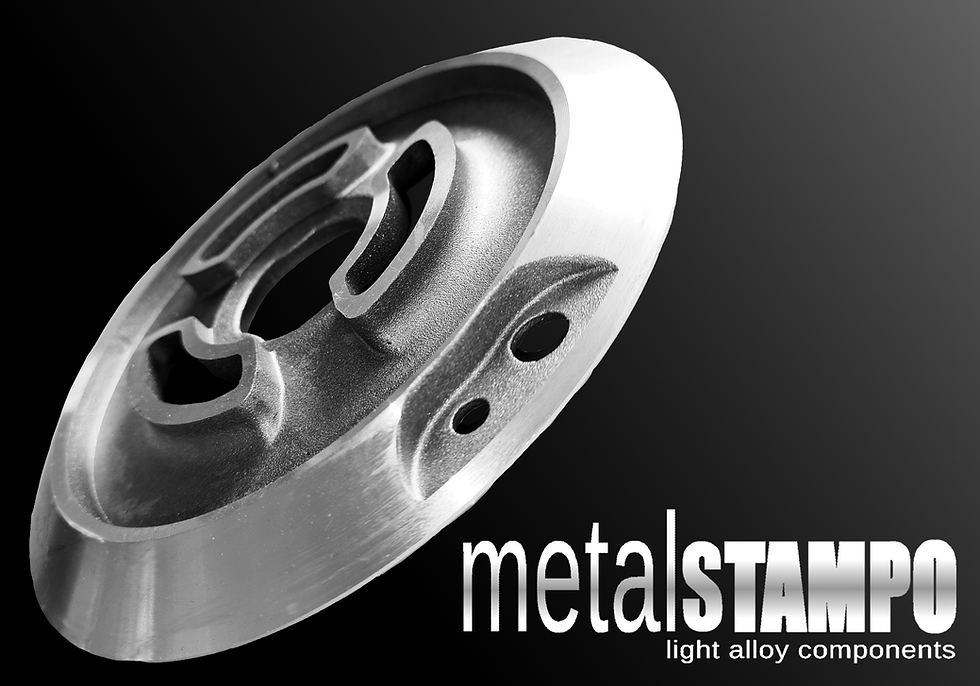

Metalstampo Srl is a well-established company in the Italian industrial landscape, specializing in light alloy die casting, with a particular focus on aluminum and zamak. Founded on decades of experience and continuous technological updates, the company has become a benchmark for businesses needing high-precision and high-quality components. With a range of services that spans from die casting to mechanical processing, Metalstampo stands out for its ability to provide innovative, customized solutions, always attentive to its clients’ needs.

Die Casting Plants: Production Capacity and Advanced Technologies Metalstampo’s die casting department is the core of the company, featuring a machine fleet that includes 7 presses of varying capacities, designed to meet a wide range of production needs. The machines in the facility range from a capacity of 125 tons to 700 tons, offering high flexibility.

Hot Chamber Presses: These two presses are dedicated to zamak processing. Thanks to their system, they maintain the metal in a molten state at high temperatures, making the production process faster and ideal for small to medium-sized parts with high precision.

Cold Chamber Presses: The five cold chamber presses are used for aluminum die casting, which requires a separate melting phase before being injected into the machine. This process is ideal for larger components with complex mechanical specifications, ensuring greater strength and lightness of the product.

The presence of these two different technologies within the same facility allows Metalstampo to successfully handle a wide range of requests, from limited series productions to large-scale industrial orders. The company has also invested in vacuum die casting, an advanced technology that minimizes porosity in castings, thereby improving the mechanical properties of the product. This technique is particularly suited for components that must withstand high mechanical stress or require perfectly smooth surfaces without imperfections, as often required in the automotive and electromechanical sectors.

High-Precision Mechanical Processing for Finished Products Another distinctive feature of Metalstampo is its ability to support the customer throughout the entire production cycle, thanks to a dedicated precision mechanical processing department. The company has an extensive range of advanced machinery, including transfer units, 5-axis work centers with two stations, precision lathes, and threading stations.

Transfer Units: These machines perform various machining operations in sequence on a moving part, optimizing cycle time. They are ideal for medium to large series production, where speed and repeatability are crucial.

5-Axis Work Centers: These advanced machines allow for the machining of a part on five axes simultaneously, enabling the creation of complex geometries with extreme precision. The two stations on which they are mounted ensure efficient and continuous production, reducing machine downtime.

Precision Lathes: Used for cylindrical machining, these lathes allow for the creation of components with perfect finishes and minimal tolerances, essential in sectors such as automotive and aerospace.

Threading Stations: These stations are dedicated to producing internal and external threads on metal components, ensuring precise and secure assembly during the final assembly phase.

With these facilities, Metalstampo can provide fully finished products, ready for assembly or direct use in the customer’s production process. This integrated approach not only reduces delivery times but also ensures quality control throughout the process, providing significant savings in terms of costs and resources for clients.

3D Control and Absolute Quality Assurance The quality of the finished product is a top priority for Metalstampo. To ensure maximum precision and compliance with clients’ technical specifications, the company has integrated a certified 3D Control Machine into its production process.

3D Control Machine: This cutting-edge tool allows for the exact measurement of each component with millimeter precision. Measurements are carried out through a mechanical arm that examines every point of the part, ensuring it falls within the specified tolerance limits. This machine is essential to ensure that each produced part meets the highest quality standards required by clients, minimizing errors and production waste.

Thanks to this technology, Metalstampo can offer exceptional repeatability of results, crucial for series production, where each part must be identical to ensure the functionality and safety of the final product. 3D control thus becomes a vital tool in preventing production defects and reducing waste, while maintaining high standards of production efficiency.

Versatility, Innovation, and Application Sectors Metalstampo’s constant commitment to technological innovation and process optimization makes the company an ideal partner for numerous industrial sectors. Among these are the automotive, electronics, furniture, and tooling industries, where the quality and precision of components are essential. The versatility of Metalstampo’s offering allows for the creation of customized products that meet clients' specific needs, both in terms of design and technical performance.

The company’s continuous updating of employed technologies and its focus on environmental sustainability in production processes are other aspects that characterize Metalstampo’s approach. The company continuously invests in research and development, seeking innovative solutions to improve energy efficiency and reduce the environmental impact of production. This combination of tradition and innovation makes Metalstampo a reliable partner capable of facing the challenges of an increasingly competitive and sustainability-oriented market.

For more information on the services and technologies offered by Metalstampo Srl, please visit the company’s official website (https://www.metalstampo.it/produzione).

Comments