Metalstampo Srl: Surface Treatments for a High-Quality Finished Product

- metalstampo srl

- Sep 17, 2024

- 3 min read

The Company and Its Vision

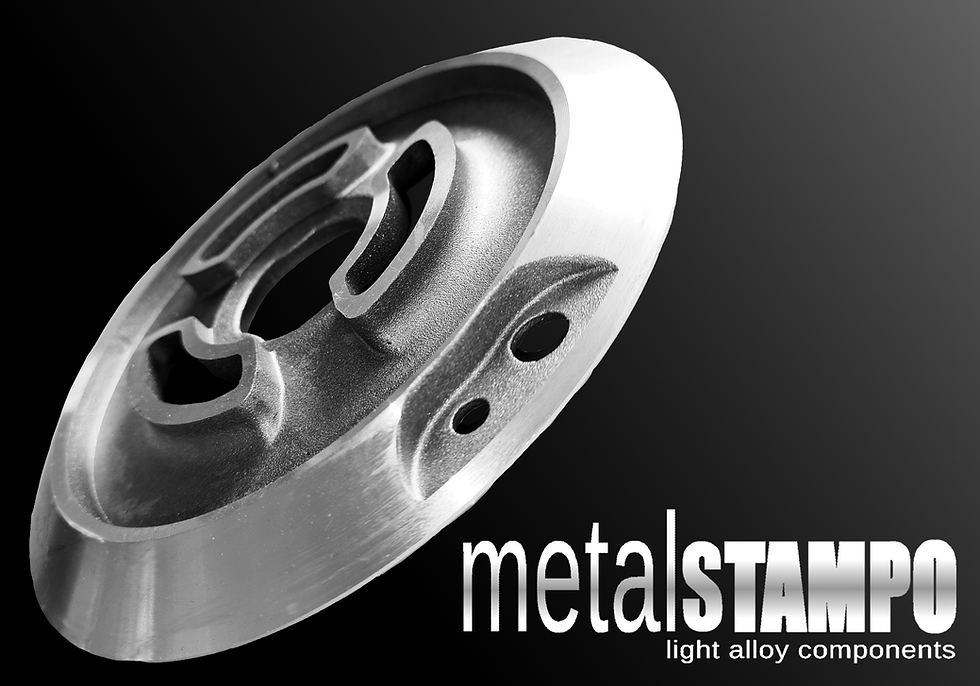

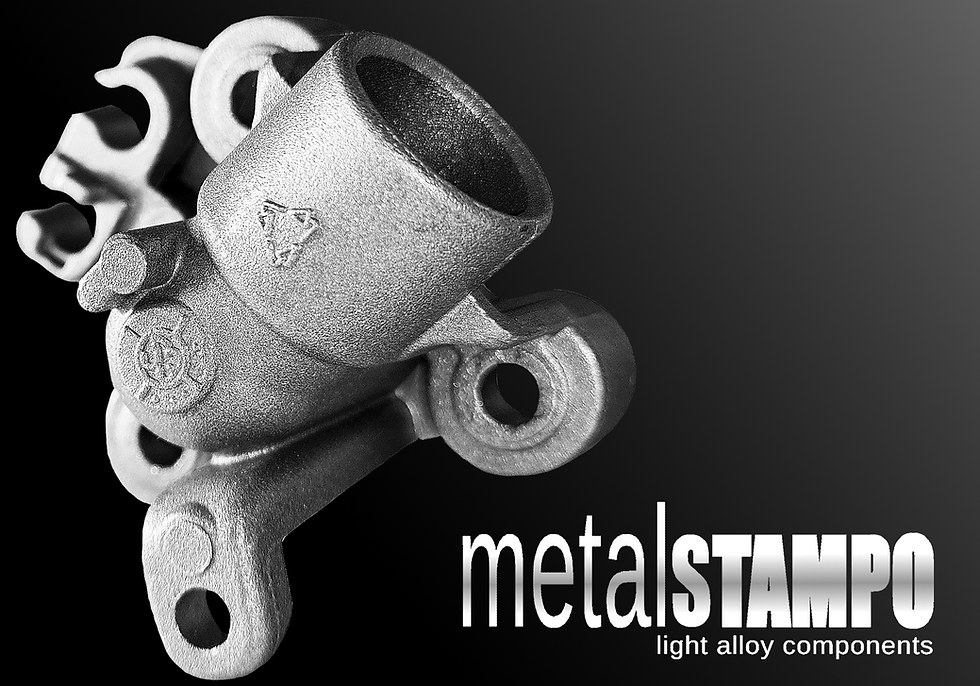

Metalstampo Srl is a cutting-edge company specializing in aluminum and zinc alloy die-casting, with over 30 years of industry experience. With a strong focus on quality, Metalstampo operates in sectors like automotive, electronics, lighting, and furniture, delivering high-performance components. Its advanced production infrastructure and strict quality control ensure precision in every production stage. This commitment to excellence is reflected in constant innovation, enabling the company to respond flexibly and swiftly to market demands.

Specialized Finishes and Surface Treatments: A Complete Approach

The manufacturing process at Metalstampo goes beyond die-casting. They manage a comprehensive range of surface finishes and treatments, enhancing both the aesthetics and technical properties of their products, ensuring versatility and quality even for the most complex applications.

Shot Blasting: This mechanical process cleans and prepares the surfaces for other treatments or improves the aesthetic finish. By using abrasive materials, shot blasting removes impurities and residues, creating a more uniform surface ready for subsequent processes like painting or chroming.

Vibratory Finishing and Tumbling: These treatments are employed to deburr and remove surface irregularities. In vibratory finishing, the component is placed in a vibrating container with abrasive materials that act mechanically. Tumbling operates similarly but is often used for small parts, such as gears or metal fasteners, improving their appearance and handling.

Shot Peening and Satin Finishing: Both are finishing techniques that give metal surfaces a smooth, uniform appearance. Shot peening uses high-speed metallic beads to increase fatigue resistance and reduce micro-cracks. Satin finishing, on the other hand, gives a matte, elegant appearance, especially appreciated in the design and furniture industries.

Polishing: To achieve a reflective and highly glossy surface, polishing is crucial. This mechanical process uses fine abrasives to remove any imperfections, making the component ideal for decorative applications or where impeccable aesthetics are required.

Zinc Plating, Chroming, and Nickel Plating: These galvanic treatments are essential for protecting metal components from corrosion and environmental factors, improving durability and appearance. Zinc plating is often used in industrial applications where strength is a priority. Chroming and nickel plating provide not only protection but also a shiny and wear-resistant finish.

Gold Plating, Silver Plating, and Brass Plating: These treatments are ideal for giving the product a precious finish. Gold and silver plating are often used for components in luxury sectors, while brass plating provides a warm tone, commonly used in high-end furniture and design.

Passivation and PVD (Physical Vapor Deposition): Passivation enhances the chemical resistance of metals, protecting them from corrosive agents. PVD, on the other hand, is a physical process that deposits thin layers of protective material, increasing resistance to corrosion, wear, and high temperatures, resulting in a durable, high-quality finish.

Heat Treatments: These are used to modify the mechanical properties of die-cast metals, improving strength, hardness, and durability, making them more suitable for high-performance applications, such as in the automotive industry.

Painting: Painting is the final step in customizing and further protecting the finished product. Metalstampo offers a wide range of colors and finishes, from matte to glossy, making each piece unique and in line with customer specifications.

Complex Assemblies

In addition to surface finishes, Metalstampo provides advanced assembly services, combining components made of different materials. This is particularly useful in industries such as electronics and automotive, where the integration of plastic and metal parts into a single product is required.

Plastic-to-Metal Assembly: This service allows for the creation of complex products that combine different materials. Thanks to Metalstampo's precision machinery and techniques, the integration of plastic and metal is solid and durable, respecting dimensional tolerances even in complex processes.

Thermoplastic Overmolding on Metal

One of Metalstampo's strengths is thermoplastic overmolding on metal, an advanced process that allows for components that combine the robustness of metal with the flexibility of thermoplastic materials.

Thermoplastic Overmolding: This process involves injecting thermoplastic material over a metal component. The result is a multifunctional piece with an optimal combination of properties for specific applications. It is a technique widely used in industries requiring lightness, thermal and electrical insulation, or specific resistance and durability properties.

Commitment to Quality and the Environment

The company distinguishes itself not only for its attention to product quality but also for its commitment to the environment. Metalstampo adopts eco-friendly production processes, minimizing waste and optimizing the use of energy resources. Additionally, continuous technological innovation improves efficiency, ensuring a reduced environmental impact.

Conclusion

Metalstampo Srl represents a benchmark in the aluminum and zinc alloy die-casting sector, offering a complete range of services, from advanced surface finishing to complex assemblies. With meticulous attention to quality and state-of-the-art technologies, the company is the ideal partner for industries requiring precision, innovation, and reliability.

Comments