Metalstampo 3D rapid prototyping

- metalstampo srl

- Sep 27, 2023

- 1 min read

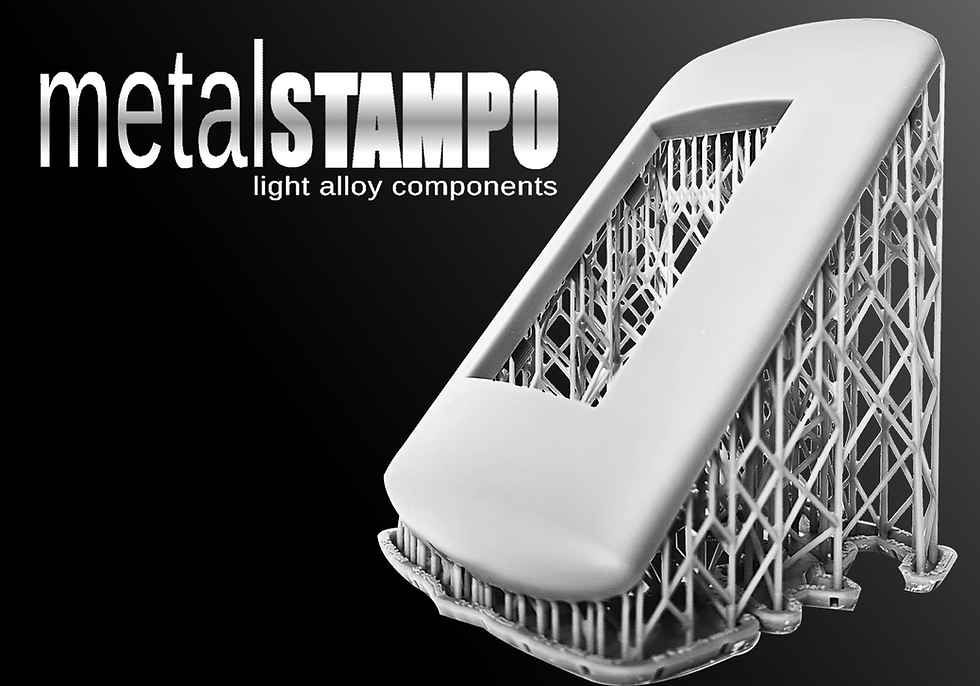

The Form 3 resin printer, using LFS (Low Force Stereolithography) technology, allows you to print components with a vertical resolution that can vary in a range of 25-160 µm. The maximum print volume is 14.5 x 14.5 x 18.5 cm. The printer is equipped with an LPU (Light Processing Unit) which, through a system of lenses and mirrors, projects a high intensity laser beam which allows extremely accurate prints to be obtained.

We provide our customers with the possibility to choose between the following resins:

-Grey: to create resistant prototypes. Suitable for parts that can be painted, varnished or subjected to surface treatments. Ideal for highlighting small details. Vertical resolution from 25 to 160 µm.

-White: to create resistant prototypes. The neutral color is suitable for parts that will be painted, varnished or subjected to surface treatments. Ideal for presentation objects. Vertical resolution from 50 to 100 µm.

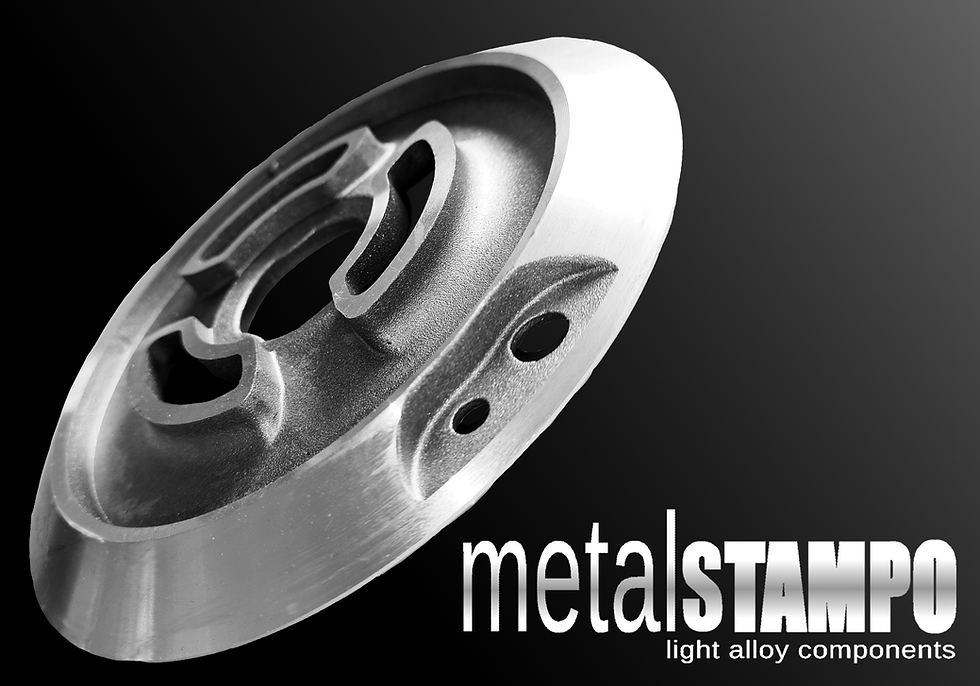

-Rigid 10k: resin with engineering characteristics (modulus of elasticity: 10 GPa, strain at break: 1%, flexural modulus: 9-10 GPa*, tensile strength: 53-65 MPa*, HDT (thermal distortion temperature) at 0.45 MPa : 163-218 °C* , HDT at 1.8 MPa :82-110 °C* )**.

Resins in other colors (such as black and transparent) and special resins for dental applications are also available to create crown and bridge models with removable abutments.

This service can be aimed not only at customers who want a die-cast aluminum or zamak component, but at anyone interested in having a three-dimensional prototype of a project.

FIND OUT MORE : https://www.metalstampo.it/prototipi-3d

Comments